Copper Alloys

Copper Zirconium

|Alloy Grade - CuZr

Material No. Unified Numbering System (UNS): C15000

Chemical Composition

| Element | Cu(1,2) | Zr |

|---|---|---|

| Min (%) | 0.1 | |

| Max (%) | Rem | 0.2 |

- Cu value includes Ag.

- Cu + Sum of Named Elements 99.9% min.

This is high conductivity heat treatable copper alloy. Heat treatment cycle consist of Solutionising, Cold work & ageing Process.

Common Fabrication Processes

- Bending

- Cold working

- Drawing

- Extruding

- Forging

- Hot working

- Ring Rolling

- Machining

Mechanical & Electrical Properties

Swipe from right to left to view more

| Form | Tensile Strength In N/MM2 | Elongation In % | Rockwell Hardness in F scale -HRF | Conductivity% IACS at 20°C |

|---|---|---|---|---|

| Rod | >240 | >10 | >85 | >90% IACS |

| Flat | >240 | >10 | >85 | >90% IACS |

| Rotor Bar | >365 | ≥11 | ≥90 | ≥93% IACS |

| SC Ring | 325-385 | ≥11 | ≥90 | ≥93% IACS |

Physical Properties

| Melting Point – Liquidus °C | 1080 |

|---|---|

| Melting Point – Solidus °C | 980 |

| Density lb/cu in. at 20°C | 0.321 |

| Specific Gravity | 8.89 |

| Electrical Conductivity% IACS at 20°C | 90(1) |

| Thermal Conductivity Btu/ sq ft/ ft hr/ °C at 20°C | 212 |

| Coefficient of Thermal Expansion 20 – 100 10-6 per °C (20 – 100°C) | 9.4 |

| Coefficient of Thermal Expansion 20 – 300 10-6 per °C (20 – 300°C) | 9.8 |

| Specific Heat Capacity Btu/ lb /°C at 20°C | 0.092 |

| Modulus of Elasticity in Tension ksi | 18700 |

|

|

Applicable Form & Size

| Form | Size |

|---|---|

| Rod |

Dia: Ø6 mm-Ø50mm Length: 2 Mtr. max Dia: Ø51 mm-Ø100mm Length: 1 Mtr max Dia: Ø101 mm-Ø145mm Length: 0.5 Mtr max |

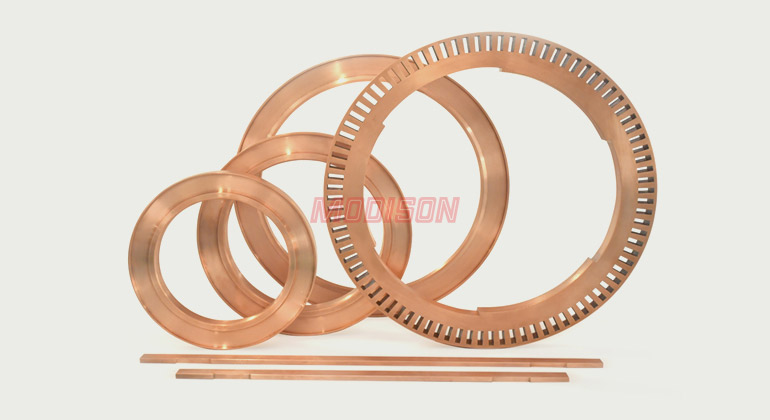

| Flat / Rotor Bar |

Thick: 5 mm - 60 mm Width: 20 mm - 150 mm Length: 2000 max |

| Wheel |

Dia: Ø400 mm max Thick: 5 mm – 50 mm |

| Short Circuit Ring |

OD: Ø270 – Ø800 mm ID: Ø160 – Ø700 mm Thick: 17mm to 90mm |

|

Apart from above we can also manufacture as per customer specification |

|

Typical Applications

|

Electrical

Industrial

|